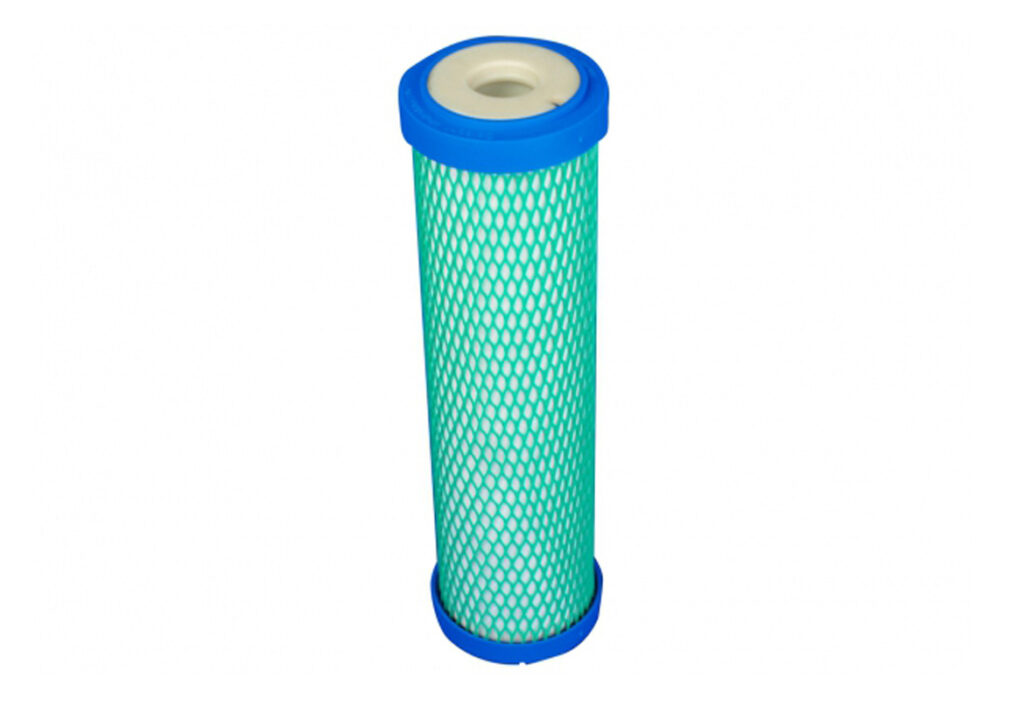

Filter cartridge for high heavy metal reduction

For water filtration in the kitchen and bathroom shortly before the removal (point of use). Priority use with high heavy metal contamination (such as iron, lead, nickel, copper, mercury). l Combined activated carbon KDF granulate filter cartridge l Activated carbon filter part (sintered) with 1.5 micron fineness l Filter granules inside order with KDF 55 add. Distance / reduction of dissolved metal compounds (heavy metals) KDF has antibacterial and against fungi and algae – reduces chlorine, pesticides and hydrogen sulfide.

The filter cartridge must be replaced after 6 months (according to DIN 1988). In principle, up to 10,000 liters of water may be filtered during this period. However Earlier replacement may be necessary when the water flow becomes noticeably reduced. Earlier replacement is not a deficiency in the filter used, but rather a sign of the increased presence of fine particles in unfiltered water.

Contamination reduction

KDF 55

Lead, copper, iron, nickel, chrome, cadmium, aluminium, mercury,, Arsen, Zinc >> up to 99 %*

Carbon filter part

Chlorine, chloroform, lindan, DDT, atrazin, Medical residues., polare pestizides >> 70 %**

*) certfified from the American National Science Foundation – NS

**) compared to the cartridge NFP Premium

| IFP KDF | |

| Art. No. | 220 FP045-9KDF |

| Shortcode | IFP-KDF |

| Weight | 450 g net |

| Height | 248 mm |

| Diameter | 73 mm |

| Material Filterblock | Carbon, KDF |

| Flow rate | approx. 1,5 l/min (pressure depend) |

| Performance | approx. 10.000 Liter |

| Filterf fineness | 1,5 μm |

| Packaging unit | 24 pieces |

| Box LxHxB | 285 x 80 x 80 mm |

| Box PU 24 pieces | 600 x 300 x 400 mm |

| Weight | approx. 16 kg incl. box |

| Customs number | 8241 9900 |

| EAN number | 4250188803382 |

| Cahnging interval | 6 month |

| Manufactured in | Germany |

| Pollutant retention | Heavy metal |

| Manufacturer | Carbonit® |

| Pallet | 24 x 24 = 576 pieces |

| Manufactured for | 9 3/4“ Filter housing |

| Main location | Kitchen |

| Restrictions for use! | Use only cold water – Not behind unpressurized boilers! |

Manufacturer: CARBONIT Filtertechnik GmbH – Industriestraße 2 – 29410 Salzwedel / OT Dambeck – Germany